U-type Dry Mortar Mixer

Fetures

1. The drum and paddle are all made of carbon steel or stainless steel, which is easy to clean and avoids corrosion.

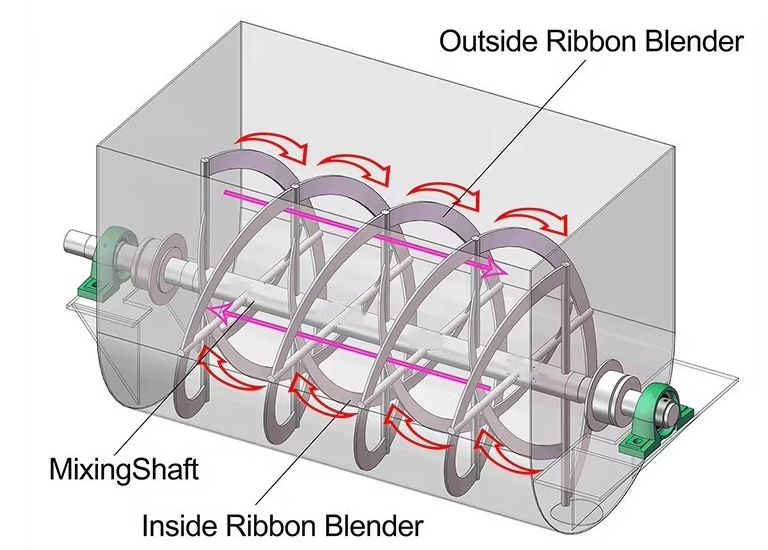

2. Two-way S-shaped propeller blades, the material is mixed quickly and evenly without dead ends, and scrapers can be installed on the spiral belt,with higher working efficiency for mixing dry powder.

3. The special design of the protective door makes it easy to maintain the equipment, and it is specially equipped with a man ladder to make feeding more convenient.

4. The visible window on the top is easy to observe the mixing situation.

Main Parameter

| Model | 1000 | 2000 | 3000 | 5000 |

| Volume | 1000L | 2000L | 3000L | 5000L |

| Motor | 7.5kw | 11kw | 15kw | 22kw |

| Reducer | 350 | 350 | 350 | 400 |

| Speed | 33r/min | 33r/min | 33r/min | 27r/min |

| Plate thickness | 4mm | 6mm | 6mm | 8mm |

| Size | 1.8*0.9*1.05m | 2.2*1.2*1.35m | 2.5*1.26*1.45m | 2.9*1.5*1.65m |

| Materials | Carbon steel/stainless steel cutomized | |||

Packing

| Model | 1000 | 2000 | 3000 | 5000 |

| Volume | 1000L | 2000L | 3000L | 5000L |

| Motor | 7.5kw | 11kw | 15kw | 22kw |

| Reducer | 350 | 350 | 350 | 400 |

| Speed | 33r/min | 33r/min | 33r/min | 27r/min |

| Plate thickness | 4mm | 6mm | 6mm | 8mm |

| Size | 1.8*0.9*1.05m | 2.2*1.2*1.35m | 2.5*1.26*1.45m | 2.9*1.5*1.65m |

| Materials | Carbon steel/stainless steel cutomized |

|||

.png)

.png)